product description

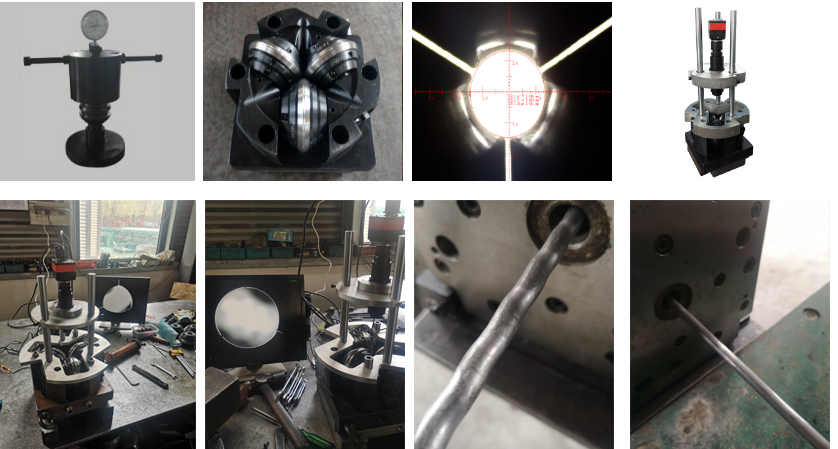

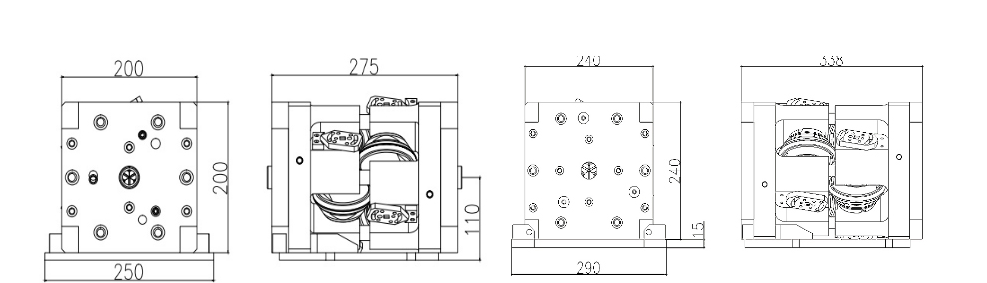

CRM rolling cassette is the most accurate and miniaturized model, and it is a model to replace traditional wire drawing and wire drawing die. The original intention of this model is to solve the difficulty of metal wire over-molding, and it is suitable for high, medium and low carbon steel wire, stainless steel wire, welding wire, steel cord wire, aluminum-magnesium alloy wire, titanium, chromium, zirconium and other wires. The dimensions of the rolling cassette of this model are almost similar to the dimensions of the rolling cassette of the existing wire drawing machine. Easy to replace.

1- cassette roller die is a device that installs six carbide rollers in a closed mold box and can be precisely adjusted and fixed. The built-in 12 bearings realize continuous internal circulation of lubricating oil, and the bearings are lubricated And take away the bearing rolling heat. Six cooling shafts enable continuous water cooling to continuously remove the rolling heat from the rolls.

2- The wire over-drawing die reduces the diameter by friction, while the wire over-rolling die reduces the diameter by rolling extrusion, which increases the speed of the production line.

3- When the wire drawing die is in a rainy day or in a humid environment, the wire drawing powder is not easy to attach to the surface of the wire, and it is easy to break the wire. The use of roller die does not require drawing powder, which fundamentally solves the problem of dust in the workshop, improves the working environment of workers, and saves production costs.